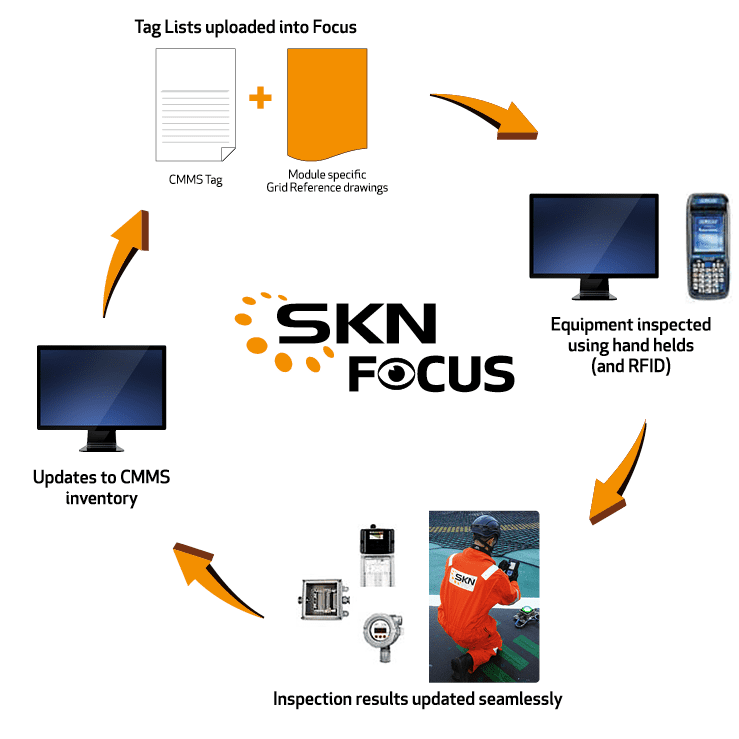

SKN Focus ensures our clients can draw on our engineering expertise and highly trained personnel in the field, to support timely, accurate data acquisition that can be interrogated immediately. It is already utilised by a number of our clients with over 67,000 items inspected since its introduction.

SKN E&I Technicians in the field operate market leading Personal Digital Assistants (PDA’s) suitable for hazardous areas alongside the latest RFID technology to capture and manage all types of inspection data. Intuitive screens and operator prompts; drop down lists; document storage; adaptable reporting and a clear audit trail results in the following benefits for clients-

- Mobile data delivering regulatory compliance, asset integrity and operational proficiency.

- Increased efficiency of inspection and maintenance activities.

- Removal of multiple handling of data.

- Promotion of a safer working environment.

When planning a series of inspections the engineer needs to be able to decide quickly and objectively what and how items are to be inspected. Each client needs to be able to define how the risk level of an item should be calculated as a score; the scores divided to create a number of risk groups; and a mix of inspections to be carried out for each group. In the case of Focus Inspection Software, it allows each client’s inspection strategy to be uploaded in order to automatically generate work orders in-line with the strategy.

Inventory items and inspection requirements are uploaded into Focus using Extract, Transform and Load (ETL) logic, in order to use the data held in a client ERP / EAM system into work orders. This enables detailed analysis at component level, identifying trends with components across items. The data generated can then be interrogated and adapted to client requirements:-

- Enables the client to identify faults quickly and accurately in a way that can be analysed easily.

- Utilises IEC 60079-17:2014 to define a number of codes for consistency.

- Includes a fault analysis category that can be defined specifically for those equipment categories where faults need to be grouped, it is not required for every code.

- It defines a Repair Priority (P1 to P4) based on Zone Type, Ignition Risk and Fault Type, which can be defined by the client. The repairs can then be managed according to priority.

- SKN Focus uses pre-defined templates to produce consistent descriptions.

- Not only holds information about a piece of equipment at top level, it can also retain and maintain accurate information about the components that comprise them.

![]()